Would you like to get detailed information about our facilities and products?

YJ series jaw crushers are mostly used as a primary crusher and they are compressive crushers crushes the materials while compressing it by the mean of its eccentric shaft. It can not be obtained fine products from this crushers and the discharge opening’s setting can be adjusted. These crusher are driven by an electrical motor via V-belt and pulley.

YJ series jaw crushers are mostly used as a primary crusher and they are compressive crushers crushes the materials while compressing it by the mean of its eccentric shaft. It can not be obtained fine products from this crushers and the discharge opening’s setting can be adjusted. These crusher are driven by an electrical motor via V-belt and pulley.

The feeders which are designed with grizzly bars feed the material filled in its hopper to the primary crusher. The soil and other fine impurities can be separated and removed from the process by the mean of adjustable grizzly bars or can be Bay-Passed to maximize the capacity. The feeders are supported on the main chassis by heavy duty suspension springs and they are driven by a couple of external electrical vibrators which their centrifugal force is adjustable by its adjustable eccentric weights.

The feeders which are designed with grizzly bars feed the material filled in its hopper to the primary crusher. The soil and other fine impurities can be separated and removed from the process by the mean of adjustable grizzly bars or can be Bay-Passed to maximize the capacity. The feeders are supported on the main chassis by heavy duty suspension springs and they are driven by a couple of external electrical vibrators which their centrifugal force is adjustable by its adjustable eccentric weights.

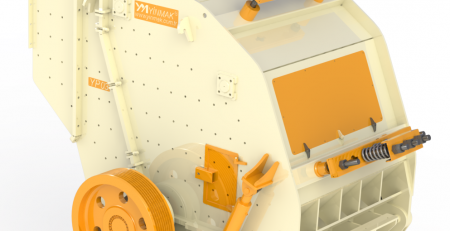

The YP series primary impact crushers are used as a primary crusher to crush soft or medium hard and non abbrassive materials. The dimension of final crushed product can be somewhat controlled. These crusher which are produced in several different sizes are driven by an electrical motor via V-belt and pulley.

The YP series primary impact crushers are used as a primary crusher to crush soft or medium hard and non abbrassive materials. The dimension of final crushed product can be somewhat controlled. These crusher which are produced in several different sizes are driven by an electrical motor via V-belt and pulley.

YS series secondary impact crushers are designed specially to be used in crushing medium hard or hard and abbrassive materials. These crushers are much more successful in crushing the hard and abbrassive materials than the conventional impactors by the mean of high chrome alloyed hammers and breaking bars. The dimension of final crushed product can be somewhat controlled by mean of the adjustable braking bars. These crusher which are produced in several different sizes are driven by an electrical motor via V-belt and pulley.

YT series tertiary impact crushers are used in crushing the return of the soft and medium hard materials as a third crushing stage and to obtain high ratio of crushed sand. Due to its specially designed inside geometry they produce much more prcentage of fine product comparing with other impactors. The dimension of final crushed product can be somewhat controlled by mean of the adjustable braking bars. These crusher which are produced in several different sizes are driven by an electrical motor via V-belt and pulley.

YV series vertical shaft impactors (VSI) are used as a second and third crushing stages for hard and abbrassive materials such as basalt and river gravel. Because of their low operation costs, they are more suitable for crushing the hard and abbrassive materials than other crushers. While some of the material fed to the crusher entering the rotor, the remaining flow from the windows and is poured around the rotor, the part which entered the rotor is thrown out by the centrifugal force of the rotor with high speed and meating the part which is poured around the rotor, Thus, the crushing occur when the part leaving the rotor meats and crushes the part poured around the rotor. These crusher which are produced in several different sizes are driven by an electrical motor via V-belt and pulley.

In a crushing plant the final products are obtained as a mixture, YE series vibrating screens are designed to separate these products to the required sizes in high efficiency. The intensity of the vibration in these screens, which effects the separation by the inclined surface and vibration can be changed by the adjustable weight couples mounted on rotating shaft held in the screen frame. These screens which are produced in several different sizes are driven by an electrical motor via V-belt and pulley.

Experiences and Expertise for Years and 27 Countries

We produce Stone Crushing and Screening Washing Facility.

You can call us for any inquiries about our facilities and our products.